Bikemad: how'd you check for play between stator and axles?

I was fortunate enough to be able to see it moving on my front Smart Pie, but if you temporarily disconnect the brake lever wires so that the regen doesn't work, you should find that the noise will disappear if it was the stator moving on the axle

(or the axle moving within the torque arms).

Without activating regen, the stator and axle will be twisted in the opposite direction to the wheel rotation under load, therefore any play in the drive key/slot between the axle and the stator should automatically be taken up on the first application of power. Subsequent applications of power should not result in a clonk

unless the axle is so loose within the stator

(or the frame dropouts) that the residual drag of the magnets is able to rotate the stator

(or axle) in the opposite direction when power is stopped while the wheel is still moving.

The axles are usually a very tight press fit inside the stators, but if the hole in the centre of the stator is slightly oversize, and/or the axle outer diameter is slightly undersize, this can result in a very loose fit which would allow slight movement to occur each time the torque direction changes. Over time this can cause wear between the axle and the stator, and also in the keyway slots and drive key.

I really thought it was axle rotating but it seems the torque arms are doing good at holding solid (at least using a wrench, not sure how that compares to a kW of power)

I once carried out a

very simple stall test using a set of digital luggage scales attached by a piece of rope tied to the outer diameter of my tyre as shown here:

My modified Pie was drawing 65.94 Amps @ 25.6V (1,694 Watts) and although the controller cut the power before the luggage scales had time to lock the reading, I was able to read a reading of at least 28kgs/61Lbs of force on a couple of the tests, which I worked out to be around 93Nm of torque!

If this force is exerted on a 10mm deep dropout the lateral force acting upon the end of the dropouts by the edges of the flats is probably around 950kg

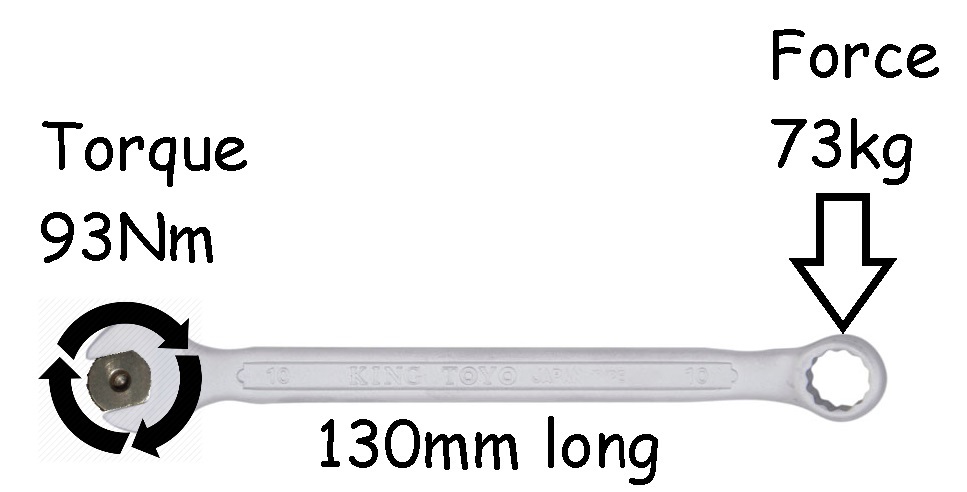

(475 kg on each end of the axle).To visualise this amount of torque, if you were to place a 130mm long 10mm spanner onto the flats of the axle, you would have to apply a force of 73kg

(160lbs or 11.5 stone) on the opposite end of the spanner to produce 93Nm of torque!

My modified controller would draw more than 65 Amps under load, so the motor produced more torque at low speed than a standard Magic Pie, but it should at least give you a rough idea of just how much torque is being transmitted through the axle.

Alan