It's good to hear you are still in one piece after your incident,

It's a shame the newer vector controllers don't have the same options for reverse that the earlier

(non-vector) controllers had, where you were able to select either "

Immed" or "

Unimm" mode.

I always had mine set to "

Unimm" for safety reasons, as this meant that the wheel had to stop rotating in the forward direction before it could engage reverse, whereas "

Immed" allowed reverse to engage immediately without waiting for the wheel to stop first, which could be extremely dangerous with a front mounted hubmotor.

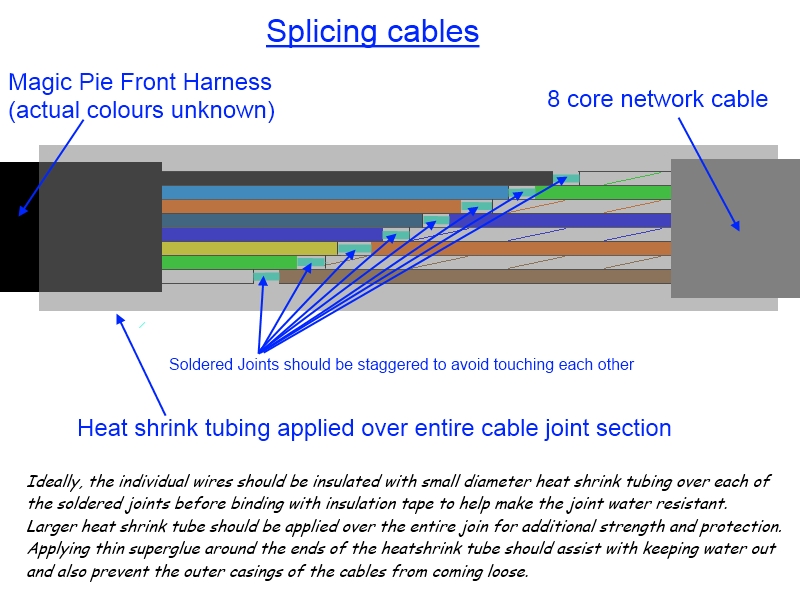

When it comes to splicing two cables together, unfortunately, not all of the soldered joints end up nice and smooth on the outside, and a little spike of solder can easily poke through a couple of layers of insulation tape when subjected to a bit of movement.

Staggering the soldered joints in the wires

(as shown below) greatly reduces the chance of poorly soldered/insulated wires from touching each other, and it also produces a much stronger and neater join in the cables.

Unfortunately, you appear to have found this out the hard way how easily a short circuit between two soldered joints can occur.

Having discovered the undesirable consequences of two tiny wires touching against each other at the wrong time, I don't think you will want to experience the same outcome again.

Alan

Alan