A fully charged LiFePO

4 rectangular cell should read

3.6~3.65V per cell, a fully charged LiMn cylindrical cell

(or LiPo) should read

4.1~4.2V per cell.

Be very careful not to touch the meter probes together

(or bridge two adjacent contacts with a single probe) while touching the pairs of contacts, as you will get some nice big sparks and also risk melting the two connected balance wires.

You can use a couple of short pieces of cable insulation or heat shrink tube

(or make one from insulation tape) slid onto the end of each of the probes to stop the tip of the probe from slipping off the soldered pins.

The balance wire connector must be plugged into the

BMS if the voltage checks are performed on the

BMS contacts.

Alternatively, you can unplug the balance lead from the

BMS and measure the voltages directly on the balance lead connector instead of the

BMS.

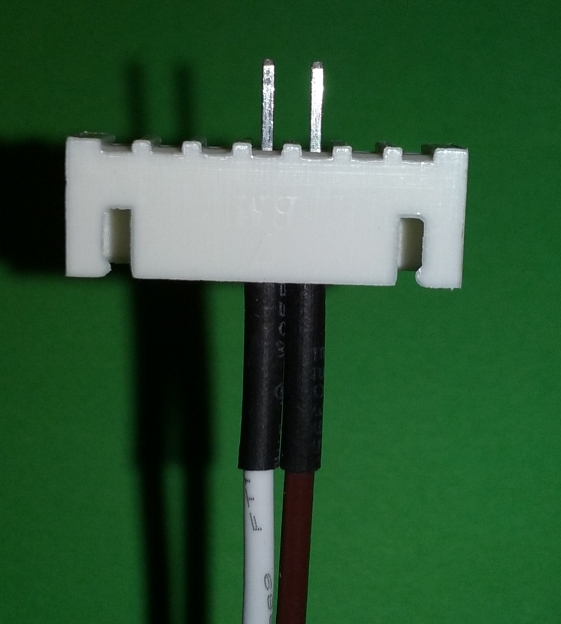

I use a modified LiPo balance lead connector

(pictured above) which plugs directly into adjacent pairs of contacts on the battery's balance lead connector to avoid fiddling around with meter probes.

It makes it a lot easier to read the meter and record the voltages without having to keep an eye on the meter probes at the same time, or lose track of which cell you were checking previously.

If you have one of these LiPo battery checkers:

You can simply plug it into the connector and measure up to 8 cells at a time and then move it along the connector to check the remaining cells.

Alan

Alan