OK, time to show my ignorance again. I know quite a bit about delta-wye transformers, but what the hell are you guys talking about delta and wye motor windings?

Dennis, the hub motors we are using work on the same principle as a simple mains voltage three phase AC motor.

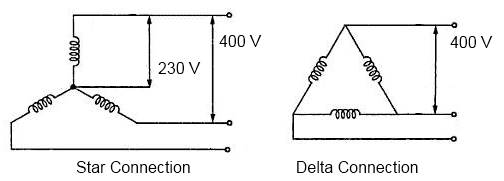

The three phase windings on the GM hub-motors are typically wound in a star configuration, and if you look at the following diagram you can see the two basic forms of connecting the windings in a three phase motor

(and generators):

(Star is also referred to as "Y" or Wye) (From the Greek alphabet where Delta is a triangle)

In the above diagram, If we replace the 400V shown with the battery voltage we are using on our hub-motors, the 230V volts shown would be equivalent to ~57.5% of the battery voltage.

So, with a 48V battery, the voltage across the single winding shown would be ~27.6V in the standard Star connection.

If we were to reconfigure the windings to produce a Delta type connection, the full 48V would be applied directly to the single winding.

With most electric motors, increasing the voltage will increase the speed proportionally, so by increasing the voltage from 27.6V to 48V we therefore also increase the speed of the motor by approximately 74%

, but unfortunately this also results in a reduction in the motor's torque.

Check out

this post for more details on a Delta modification performed on a Magic Pie.

Alan