Hi Abe,

if the frame is not touching against the end of the freewheel unit and your axle nuts have worked loose, either they were not tightened sufficiently in the first place or the axle was not fitted with suitable torque arms to prevent it from moving.

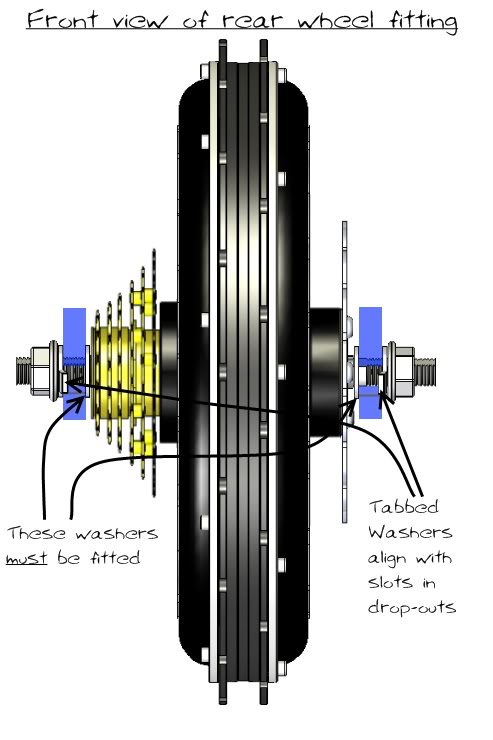

It is also very important to use the thick steel washers supplied on both sides of the dropouts to prevent the axle from cutting into the frame

(especially if your dropouts are made of aluminium):

To remove the freewheel, you will need to use a freewheel removal tool that suits your freewheel, but with a 14mm hole in the centre instead of the typical 10mm holes used for standard bike axles.

I used a "Dremel" type tool fitted with a grinding bit to enlarge the hole on my standard freewheel removal tool rather than remove the axle/stator assembly from the opposite side of the hub to allow the standard removal tool to be used.

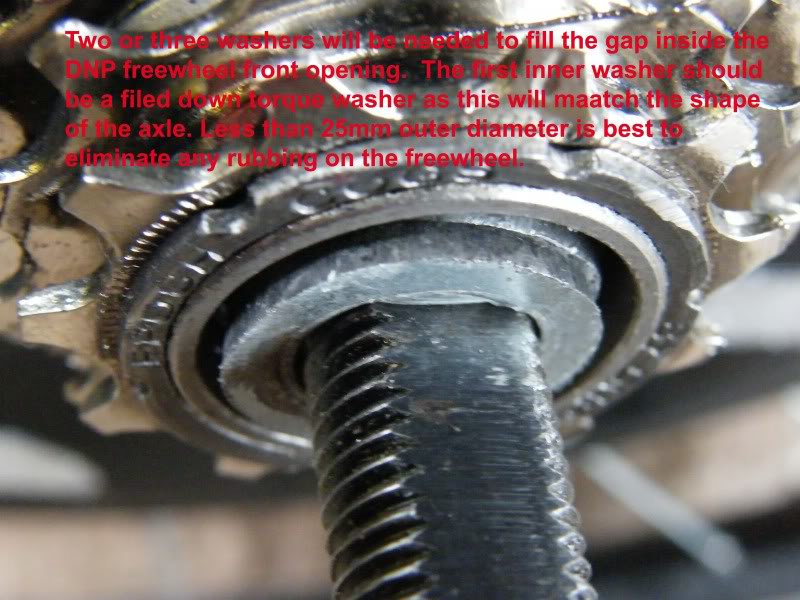

If the wheel is not smooth to turn, it might be the freewheel body is rubbing against either the frame, or the outer edge of the spacer washers on the axle.

You may need to fit an additional spacer washer and/or reduce the outer diameter of the spacer washers with a file to prevent any unwanted contact:

If your dropouts can accommodate the extra width of the 8 speed freewheel, then you might as well stick with it.

Alan

Alan