Yep. I would probably have tried that already if I had horizontal dropouts. Not sure how it would work with vertical dropouts.

You could grind the heads off two spanners and bond them into your dropouts just like Dr Bass does with his custom made plates:

Or perhaps you could do as Denis suggested and weld some plates to the spanner heads that would bolt into the existing holes.

Ignoring regen for the moment am I right in thinking the forces on the axle will try to spin it clockwise when viewed from the left side? I'm thinking the stator pushes the rotor anti-clockwise so it must exert a clockwise force on the dropout to avoid spinning. Correct?

Under power, the torque reaction on the axle will be acting in the opposite direction to the wheel rotation, so it will exert a clockwise force on the dropout which will try to make the dropout open up

(or break off) if they are not strong enough to withstand the torsional force being transmitted through the axle.

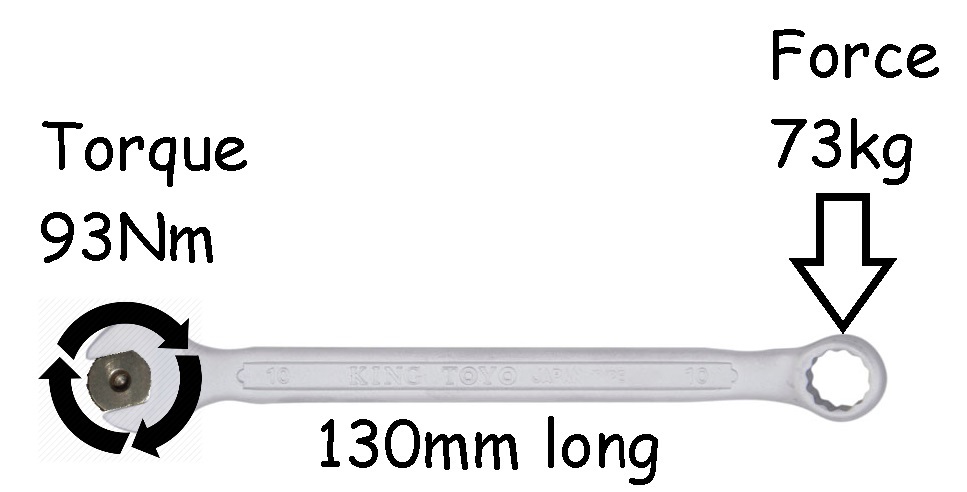

I once measured the

stall torque on my modified Magic Pie and calculated it to be around 93Nm. If this force is exerted on a 10mm deep dropout the lateral force acting on the end of the dropouts is probably around 950kg

(475 kg on each end of the axle).To visualise this amount of torque, if you were to place a 130mm long 10mm spanner onto the flats of the axle, you would have to apply a force of 73kg

(160lbs or 11.5 stone) on the opposite end of the spanner to produce 93Nm of torque!

The torque developed by the Smart Pie will obviously be a lot less than my modified Magic Pie, but it still has to be transmitted safely to the frame through the dropouts.

Alan