The nipples can only come undone if the tension of the spokes is too loose, so just refit the nipples and re-tension the spokes so they are all evenly tensioned with the rim nice and true.

You should be able to do this without removing the wheel, but it will be a bit of a fiddle removing and fitting the tyre and tube assembly with the wheel still in the frame:

With the tyre, tube and rim tape removed, you should be able to persuade the nipples to fall out of the access holes in the rim.

If you have a spare spoke, you should be able to screw it into the wrong end of the nipple a couple of turns.

Wrap some sticky tape around the end of the spoke to prevent the nipple from threading on any further, and you should now be able to poke the nipple into the rim and line it up with the spoke and carefully wind it on as far as it will go.

Now, hold the small end of the nipple

(the spoke key end) with one hand, and you should be able to simply unscrew the spoke you have just used as a tool to fit the nipple in place.

Repeat this procedure for the other nipples and then gradually tighten them until they are approximately as tight as all the rest, whilst checking that the rim still runs true. You may be able to do this with a flat bladed screwdriver, failing that use a 13g spoke key.

As several nipples have already come loose, there's a very good chance that all the other spokes are going to be too loose and will probably need to be tightened up a bit more.

Start with the spoke next to the valve hole and work your way around all of the spokes in turn and try to tighten each of them by 90 degrees

(assuming they will turn that far without getting too stiff).

When you reach the valve hole, re-check the tension of the spokes by either plucking or flicking them. If they don't sound tight enough, go round again until all the spokes are correctly tightened ensuring the rim remains perfectly true.

All newly built spoked wheels should be checked

(after a few miles of use to allow the spokes to bed in) to ensure they are still running true and that the spokes are still tensioned correctly

(especially if the wheel is equipped with a disc brake).

If the spokes are not re-tightened after the initial settling in period, they may not have enough tension to prevent the nipples from undoing. If load is placed on the rim when the spokes are too loose, the rim can distort slightly, allowing the spokes nearest the ground to become so loose that the nipple is no longer in contact with the rim and able to undo easily.

Thread locking compound has been suggested to prevent the nipples from undoing, but if the spoke tension is tight enough it should not be necessary. Thread locking compound

would not prevent spokes becoming loose on a newly built wheel, and it would also make it more difficult to re-tension the spokes correctly, however, it would probably prevent the nipples from falling off the loose spokes.

I

never use locking compound on spokes. I just apply a drop of oil to the spoke threads before fitting them to make it easier to tension the spokes without the spokes twisting and winding up like a torsion spring.

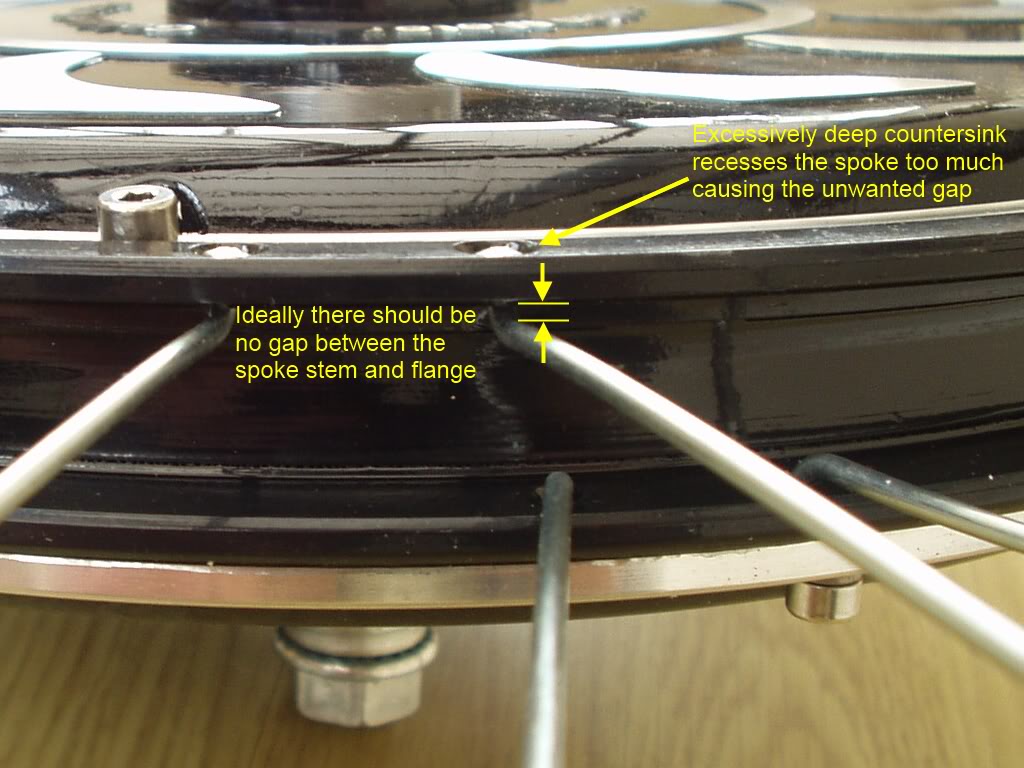

I also like to lace my wheels with the spoke heads on the inside of the hub flanges and the spokes on the outside as it makes a much stronger wheel and also supports the spoke elbows much better where they attach to the flange.

Here are two of my Pies with the spokes fitted on the outside of the flanges as described above:

I have been using GM wheels

(mainly offroad) for the last six years, and I have never broken a spoke or had a nipple come undone and fall off.

Alan

Alan