Most commercially available battery packs come with built in Battery Management Systems

(BMS) which is used to monitor the voltage and more importantly protect the individual cells from being either overcharged or overdischarged, and the

BMS circuit board will probably look something like this:

Lithium cells are very sensitive to overcharging, and Lithium Polymer

(LiPo) cells in particular have been can suffer from thermal runaway which can cause the battery to suddenly burst into flames if it significantly overcharged above the maximum safe voltage for too long.

Lead Acid batteries would overheat and boil the electrolyte if severely overcharged, but would not burst into flames.

Lithium cells do not like being discharged too low either, and if this happens, it can permanently damage the cells making them very unstable and unsafe to use.

The

BMS within the battery is designed to stop this from happening by preventing further current from passing if any of the battery's cells are above or below the pre-set operating voltage range.

The disadvantage of having a

BMS is more space is required, more weight has to be carried, there are more wires and connections, and it's more complicated and more expensive, but the safety advantage of using a

BMS is much more important when you consider that the typical eBike user will probably know very little about battery safety and the possible dangers involved with not using a

BMS.

Unfortunately, without dismantling your battery and checking each of the cell voltages with a voltmeter during the charging and discharging process you will not be able to tell if your battery's

BMS is actually working correctly or not.

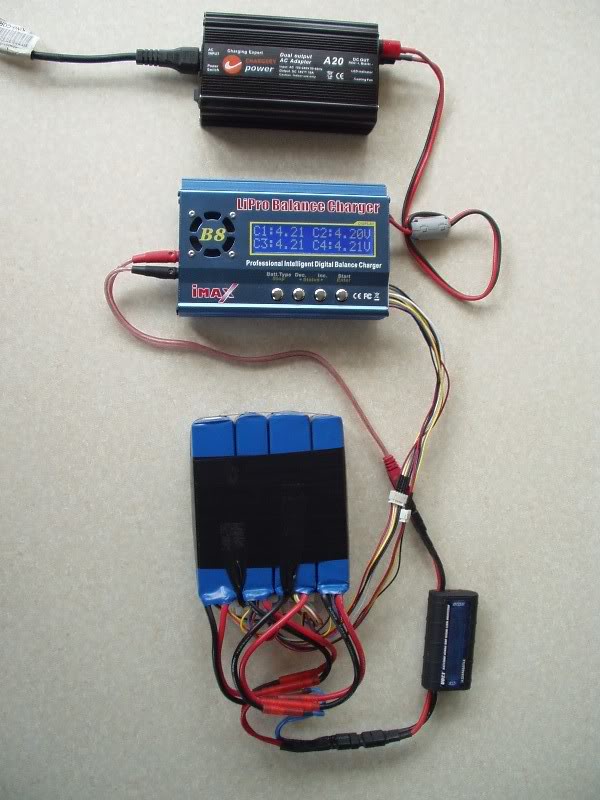

I don't use a

BMS with my home made LiPo packs because I have been using Lithium batteries with radio controlled models for years and have always used balanced chargers which actually monitor the individual cells while charging:

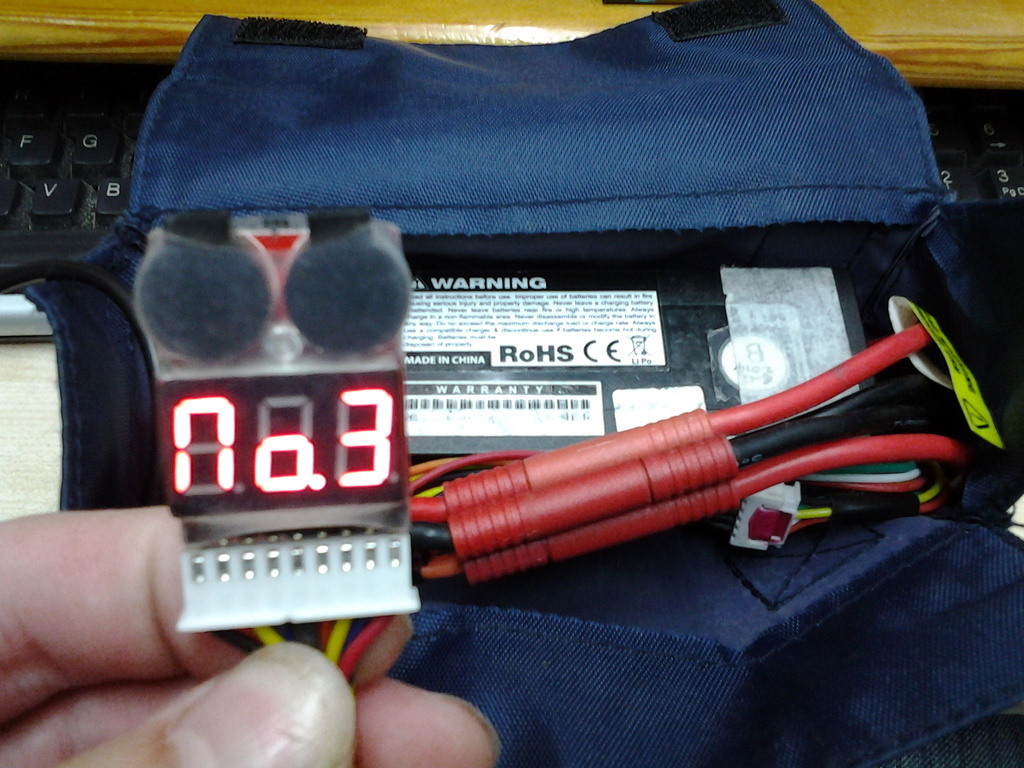

I used to use a very basic battery monitor to check the pack voltage which had an audible alarm that would sound if the pack voltage dropped below a pre-set voltage:

But this wouldn't notice if a single cell was weak and dropping more than the others, so I now use a different battery monitor unit that checks the voltages of each of the individual cells:

I don't use a dedicated

BMS unit because my battery packs are very basic, small and lightweight, and I always use a balance charger and never leave them unattended while charging, so I have saved the additional expense and complication of having a dedicated

BMS unit wired permanently into each of my home made battery packs.

The larger frame bag on the right holds two 7S 5Ah packs which I can either connect in parallel to produce a 25.9V 7S2P 10Ah pack, or in series to create a 51.8V 14S1P 5Ah pack:

The smaller frame bag holds two

Turnigy 4S 5Ah hard case packs connected in series to give a 29.6V 8S1P pack:

As well as the two batteries, a fuse, battery connectors, balance lead adapter and the battery monitor unit, there is still enough room inside the bag for two Turnigy Watt Meters, a lightweight dog lead and an emergency supply of poo bags.

Alan

Alan