Here's a nice animation that clearly shows how the switch contacts typically operate inside an "On-Off-On" toggle switch:

In the Off position, the spring loaded plunger is extended and exerts less pressure on the the rocking contact. In addition to this, if the contacts have arced together the pressure being applied in the Off position is only a couple of mm from the fulcrum point whereas the stuck contacts are about 8mm from the fulcrum so they have a mechanical advantage of around 4:1.

This means that the little spring would have to exert four times the force required to break the contacts apart in the Off position.

If the contacts are stuck together and you push the switch across to the other side, the spring will compress more, but more importantly, the rigid plunger housing would exert direct pressure on the rocker arm forcing the contacts to be released.

You can see what I mean by placing a piece of paper on your monitor with its edge running along the upper side of the rocker when it is fully raised, you should notice that the end of the plunger housing

(switch shaft) will disappear behind the edge of the paper at the point at which it would press against the stuck rocker arm.

I suspect that the reason your switch releases when you flick it quickly is because the plunger flicks quickly into the recess in the middle of the rocker arm and the sudden impact is probably enough to shock the contacts apart. When the switch is moved slowly, the plunger gently slides into the recess with no impact force. Unfortunately I cannot think of an electrical way of overcoming the problem.

I think the best solution would be to have a separate "On-Off" switch for the power

(you could even use the other "On-Off-On" switch you already have) and use the existing switch as a two position "On-On" voltage/speed selector by simply ignoring the centre "Off" position.

Dennis, unfortunately not all electricians are equipped with common sense.

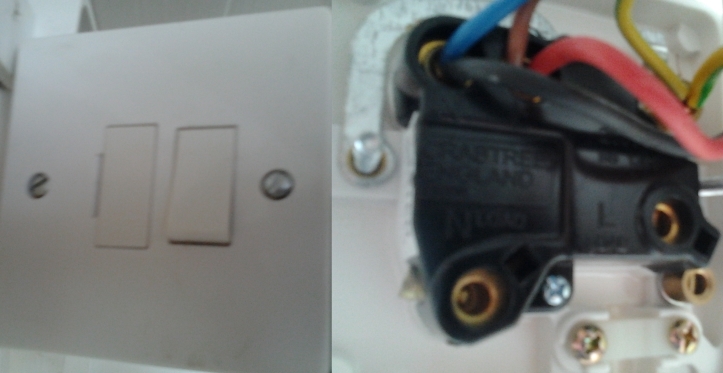

I have had two incidents over the past five years where I have been working on 240V electrical equipment, after turning off the isolator switch and removing the fuse for additional safety. On both occasions I was fortunate enough to just receive a tingly zap as a warning, and on further investigation the cause was incorrect wiring of the fused isolator switch.

In both cases the incoming mains supply and the output for the equipment had been placed together in the same connections instead of one in the input and the other in the outlet:

So not only could I have been electrocuted, but the equipment that the fuse should have been protecting was not even fused.

Imagine what might have happened if I had undone the mains cable from the appliance end and the live wire touched against Neutral or the metal chassis that I probably would have been holding.

I now test electrical appliances with a voltmeter to make sure they are "safe to enter" before I go anywhere near them as I have lost all confidence in so called electricians, and knowing my luck it might be third time unlucky!

Alan

Alan