Warning Steel frames only.

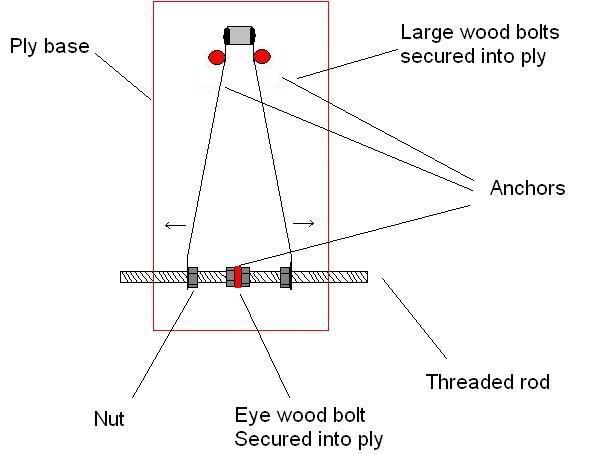

Here I drew up how I could imagine the correct method to spread drop outs evenly.

This way you can both have your 8 speed pie and eat it.

Using a 3 point anchor design will allow both sides to spread evenly.

The total cost shouldn't be that much for the proper job.

The bolts that touch the frame could be covered with some garden hose to avoid scratches. On some frames, a hole is supplied on the reinforcement plate at the base of the bottom rear fork for installation of a ike stand, this too could be used as an anchor point into the ply base.

Leaving the frame in the hot sun to heat up the metal before and when spreading the drop outs and then allowing to cool before releasing it should stop the frame from closing back up substantially. This would allow you to not have to apply too much force to gain the best set width from your work without initially having to spread the drop out too far.

On the top rear fork you would only need it to be held together with a G clamp or not at all.

My HSB36 doesn't centre also too far from the chain side. I placed both the torque and outside washer on the inside of the opposite of the chain side and for the chain side I used a thin washer I ground down by half its thickness as not to compromise its strength. By hand and great super human strength, I pulled the rear fork over the all washers. This solved my problem.

Or get a 5 speed cassette and removal tool.