Hi Zack, I've just been watching

(and listening to) your video and it sounds like something is definitely touching and physically rubbing

(but it's obviously not the freewheel).

As there is no freewheel and the torque arm is not properly fitted, I presume the wheel is only temporarily fitted on the bike for demonstrating the noise, unless you have actually been riding it like that for the last 100 miles?

I couldn't tell from the video, but if you have a brake disc fitted, make sure the screws are not too long and rubbing against the controller inside the cooling fan/brake disc mounting piece:

Did the noise start gradually during the last 100 miles and slowly become worse or did it suddenly start very recently?

If one of the bearings has excessive movement, it could allow the stator to touch against the magnets inside the hub.

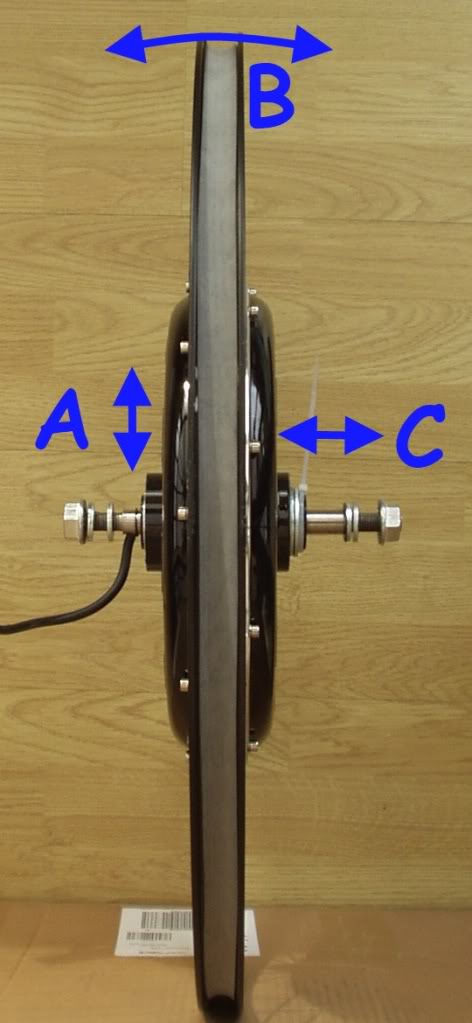

Firmly grab the tyre and try to move the wheel by twisting side to side and also pulling/pushing to see if you can see any obvious signs of movement.

If there is obvious movement, try and determine which of the following is most pronounced:

When you first received your Magic Pie, was there any signs of damage on the box

(around the axle area) where it may have been damaged in transit?

If the motor has been washed down with a hose pipe

(or worse still a jet wash) it is possible for water to get into the bearings if they are metal shielded bearings instead of the rubber sealed type:

Removing the covers can be very difficult on the MP4 as the large bearing seems to be held in place with some form of bearing locking compound, and I found it easier to remove the complete stator/axle assembly and L/H side cover together as I could not get the left side cover

(controller side) to come away from the bearing, or the bearing to come away from the stator.

Before you attempt to remove the stator, you must first free the cover from the hub as it is sealed all around the edge with silicon sealant making it very difficult to remove. I gently tapped a sharp scraper between the cover and the hub

(working my the way around) to gradually prise the joint apart.

After I had loosened the joint between the cover and the hub I removed the stator assembly by laying the wheel down horizontally with the axle placed on a piece of plywood

(to protect my floor) and then climbing onto the wheel to use my weight to push the wheel and hub towards the floor using both of my legs and one hand while I pulled on the axle/stator with the other hand.

An axle nut threaded onto the end you're pulling on makes it much easier to grip with a gloved hand.

Removing the whole stator assembly requires a lot of force to overcome the pull of the magnets, and you also need to be careful that it is kept as central as possible to avoid damaging the laminations of the stator by dragging it against the magnet as it is withdrawn.

Don't be tempted to put your fingertips under the edge of the cover to try and help pull it off, as the tremendous force from the magnets could really trap your fingers if something slips!Alan